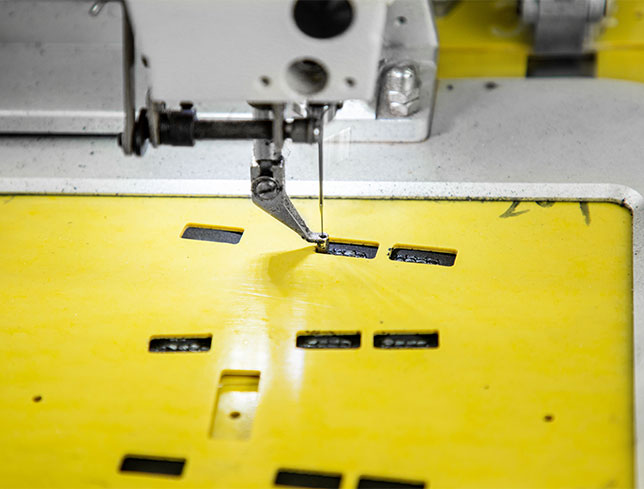

SEWING Plant Raw materials are sewn into shoe uppers with sewing machines for uniform quality.

เกี่ยวกับเรา

เกี่ยวกับเรา / About Us

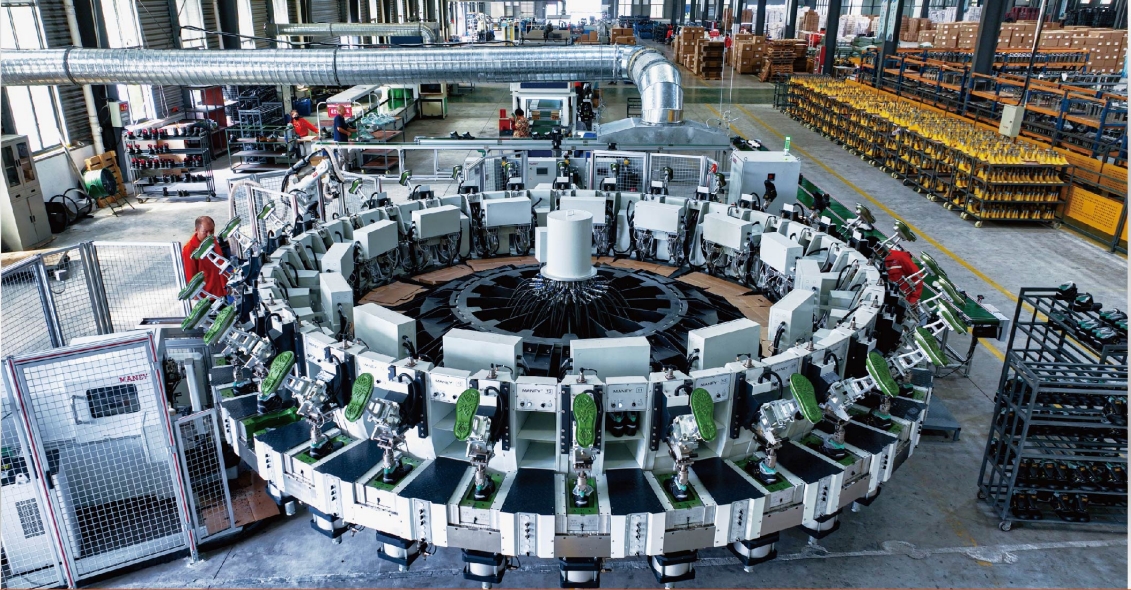

บริษัท วีอาร์ ริชชี่ อินเตอร์เทรด ก่อตั้งเมื่อปี พ.ศ. 2555 ทำธุรกิจนำเข้าและจำหน่ายรองเท้าเซฟตี้ รองเท้านิรภัยหัวเหล็ก ภายใต้แบรนด์ " VR Safety Shoes " ซึ่งเป็นผลิตภัณฑ์หลัก ที่ได้รับการจดทะเบียนลิขสิทธิ์ ภายใต้สิทธิบัตรในประเทศไทยเป็นที่เรียบร้อยแล้ว โดยโรงงานผลิตสินค้าหลักตั้งอยู่ที่ประเทศจีน พื้นที่การผลิต 50,000 ตารางเมตร พนักงานฝ่ายผลิต 500 คน เครื่องจักรในการทดสอบคุณภาพ จำนวน 20 เครื่อง สายการผลิต 6 สาย กำลังการผลิต 10,000 คู่/วัน สินค้าได้มาตรฐาน โรงงานผลิตได้รับมาตรฐานสากล ใช้เครื่องจักรในการผลิตที่ทันสมัยและมีประสิทธิภาพ สามารถรองรับและตอบสนองความต้องการของลูกค้าได้อย่างพอเพียง นอกจากผลิตภัณฑ์หลัก ทางบริษัทฯ ยังเป็นผู้จำหน่ายอุปกรณ์จราจร ป้ายความปลอดภัย เครื่องดับเพลิง หมวกนิรภัย เข็มขัดนิรภัย รวมถึงอุปกรณ์ป้องกันภัยส่วนบุคคลแบบครบวงจร ด้วยทีมงานมืออาชีพและมีประสบการณ์มายาวนาน พร้อมด้วยการบริการหลังการขาย สินค้ามีรัประกัน ราคาเหมาะสม ให้คำปรึกษา/แนะนำโดยผู้เชี่ยวชาญก่อนการตัดสินใจ

วิสัยทัศน์ / Vision

ผลิตสินค้าคุณภาพสามารถตอบสนองความต้องการของลูกค้าอย่างตรงจุด มุ่งสู่การเป็นบริษัทชั้นนำที่เติบโตอย่างมั่นคงและยั่งยืน

พันธกิจ / Mission

เราจะมุ่งมั่น พัฒนา ควบคุม และสร้างสรรค์ผลิตภัณฑ์ เพื่อตอบสนองความต้องการของลูกค้าให้ได้มากที่สุด พร้อมส่งมอบการบริการแบบมืออาชีพที่สะดวก หลากหลาย รวดเร็ว และเหมาะสมให้แก่ลูกค้า/คู่ค้า เป็นพันธมิตรที่ดีต่อลูกค้า/คู่ค้า เพื่อการเติบโตทางธุรกิจที่ยั่งยืน

OUR FACTORY

แนะนำโรงงาน

(1).jpg)

Raw Material Warehouse

Plants & Facilities

CUTTING Plant All raw materials are cut into the exact shape under quality control.

LASTING Plant A protective toe is inserted into the shoe upper to offer to protection.

INJECTION Plant Double-density raw materials to from the shape of the sole for long life and comfort.

PACKING Plant Safety shoes of proven quility are package to ship around the world.

Warehousing & Loading

TESTING Lab Safety features of our shoes are tested in our testing lab according to international standards.

Anti static feature testing machine This machine is used to

determine footwear anti static resistance, which is measured

according to EN ISO 20344:2004,5.10, S1,S1P, S2, S3, S4, S5 all require this test.

- lies above 100 kΩ

- less than or equal to 1000 MΩ

Shoe flexing testing machine

This tester is used for determining the flexibility

resistance and or indicating the cracks of shoe or

shoe sole through reciprocating flexing movements

under the specified angle and frequency.

- Bending angle:0-50° adjustable

- Test speed:0~150cpm adjustable

Safety footwear impact testing machine

This equipment is mainly used for determination of impact resistance test safety shoes toes with a certain kinetic energy& a certain height. Test its subsidence degree.

- EURO39,40/UK5.5-6.5: Min.13.5mm

- EURO41,42/UK7,8: Min.14mm

Shoe dielectric resistance testing machine

This tester is used to determine the

isolation character of the shoe material.

By slowly increasing the voltage on the sole to the specified value, it checks if it can withstand that value in the prescribed time period.

Penetration resistance testing machine The purpose of the test is to determine the penetration resistance shall be not less than 1100n. Footwear component placed in the sole provides protection againts penetration.

- Metalallic plate : Min. 1100N.

- Non metallic plate : Zero penetration

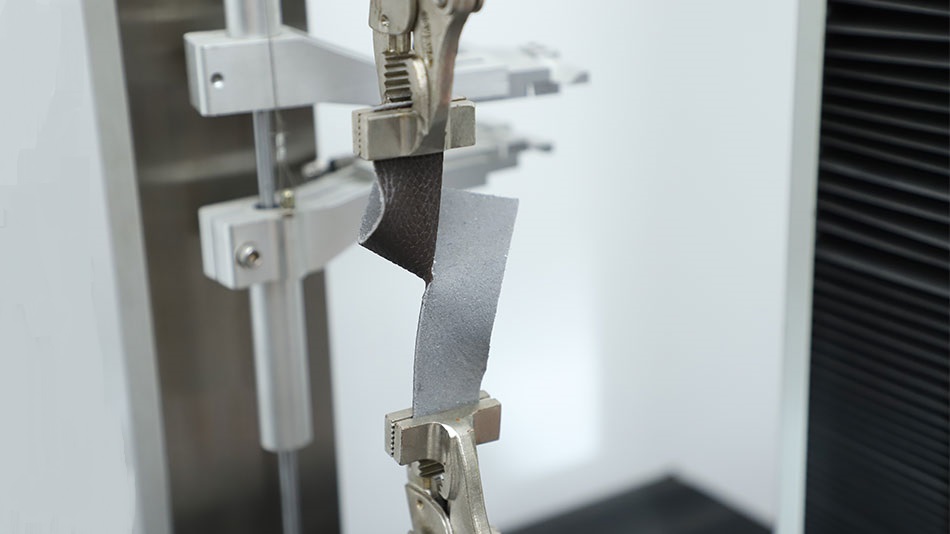

Tensile strenght testing machine The purpose of

the test is to determine the tensile strenght & elongation characteristics of fabrics, synthetic leathers, genuine leathers, webbings, laces, and threds, plastic, rubbers, elastomers, midsole and outsole foams.

- Requirement : Min. 15N/mm2.

Tear strength testing machine The purpose of

the test is to determine the tearing strength of

thematerials according to the tear method.

This test is good indicator of a material's

resistance of the tearing.

- Tear strength for leather upper : Min.120.0N

- Tear stregth for coated fabric/textile upper Min.60.0N

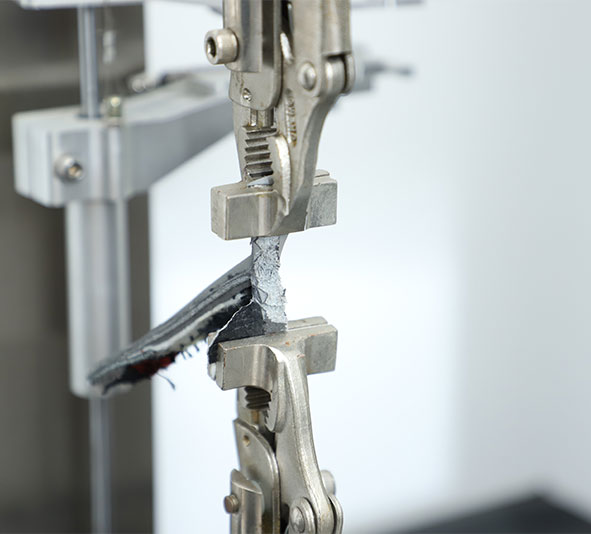

Upper & outsole bond strength tesing machine

The purpose of the test is to determine the interal tear strength between outsole and upper.

Bond strength shall be not less than 4,0 N/mm. unless there is tearing of the sole, in which case the bond strength shall be not less than 3,0 N/mm.

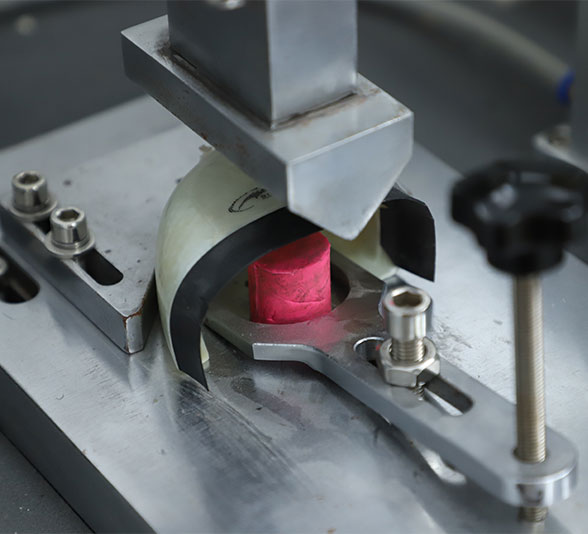

Compression testing machine

Safety footwear, incorporating protective features to protect the wearer from injuries which could arise through accidents.

It's designed to give protection aginst impact when tested at an energy level of at least 200J and against compression when tested at a compression load of at the least 15kN.

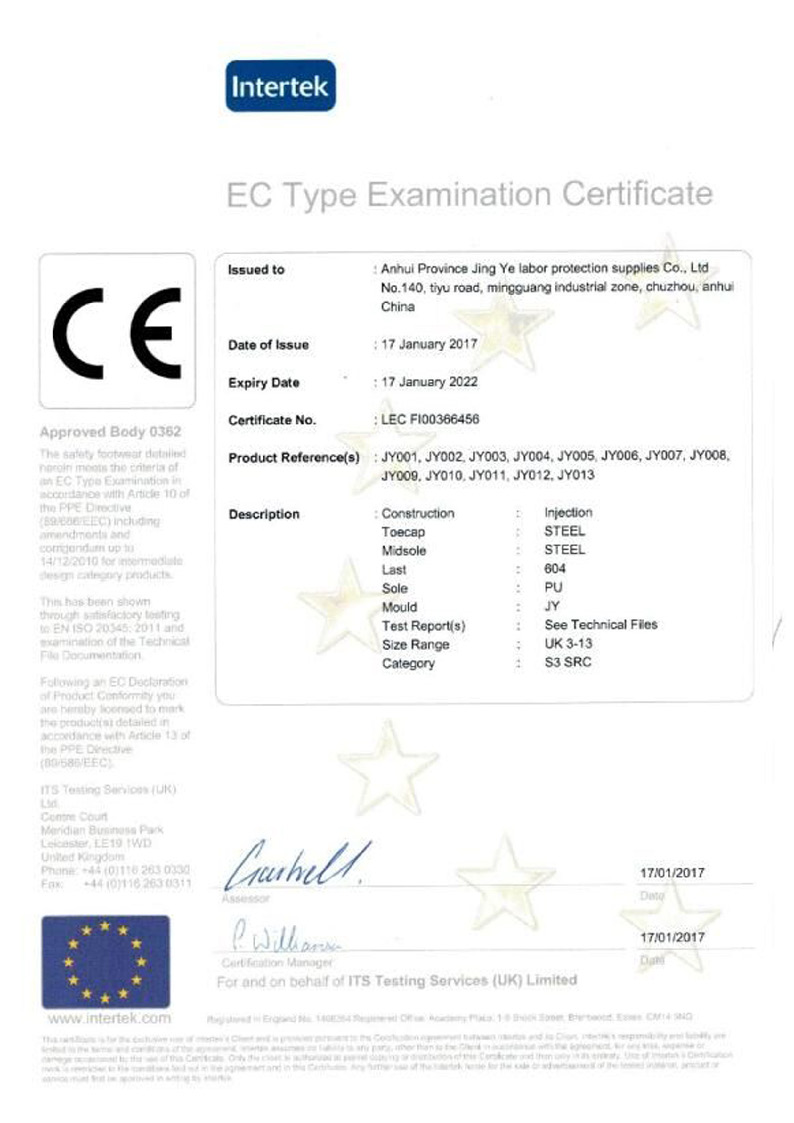

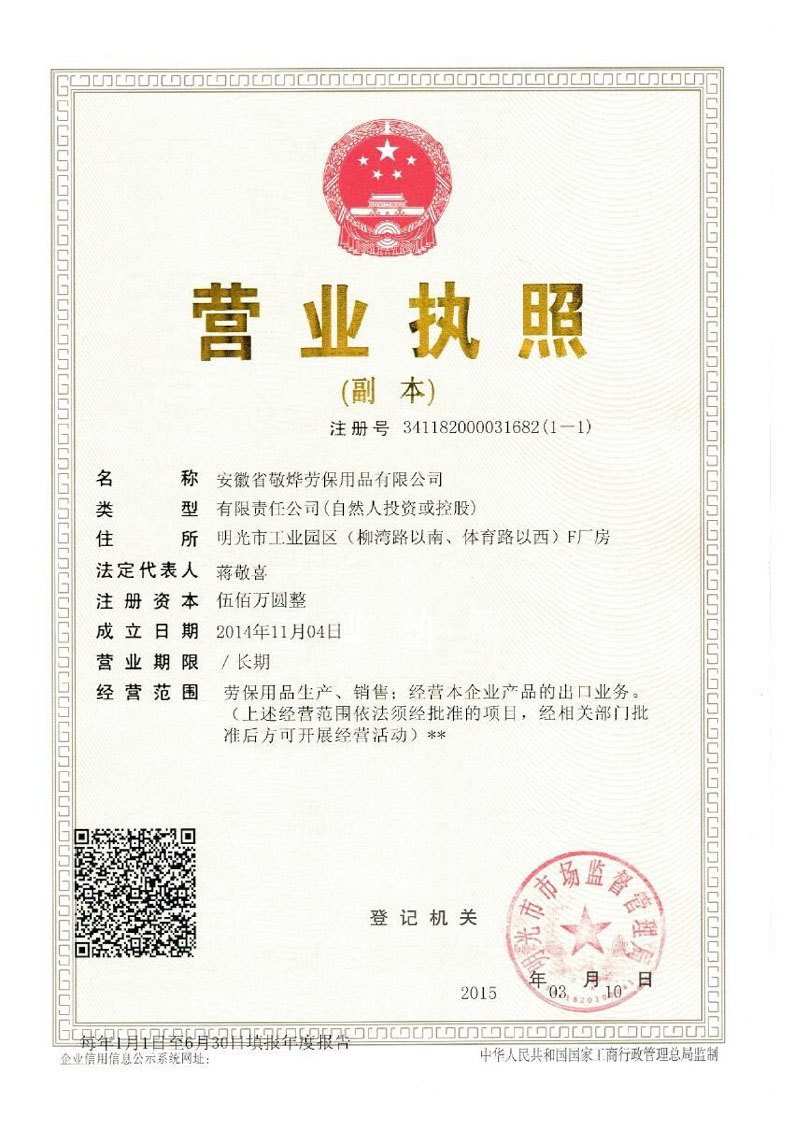

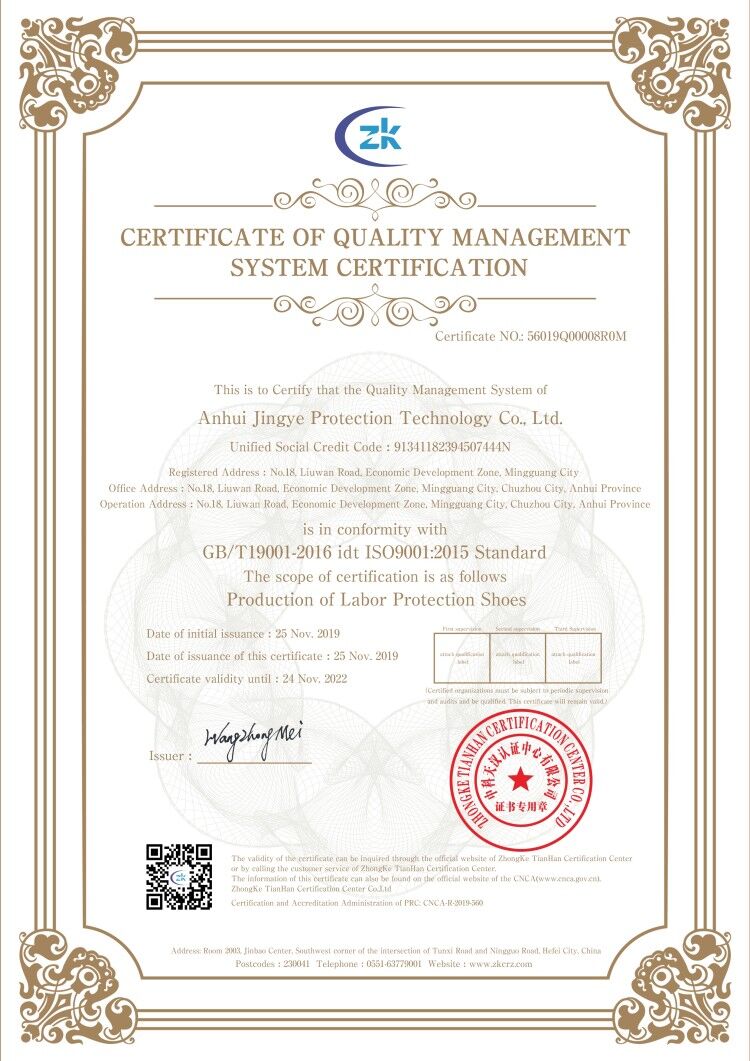

Factory Certifications

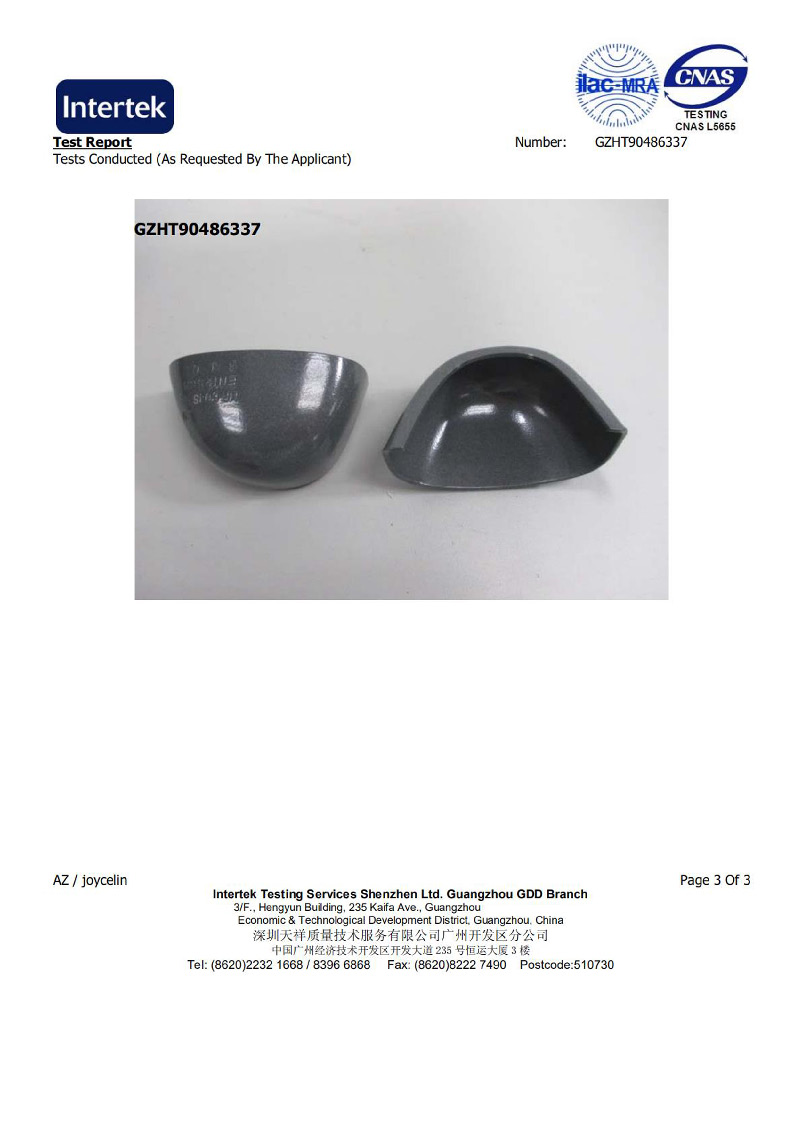

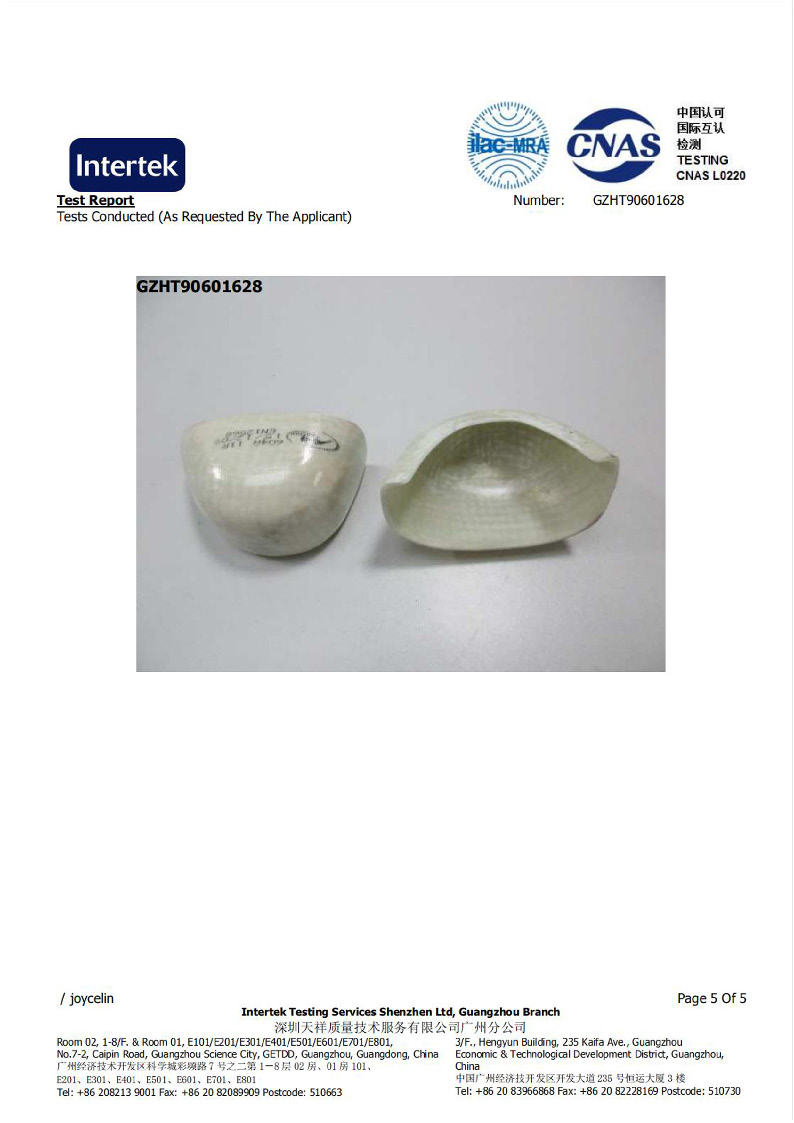

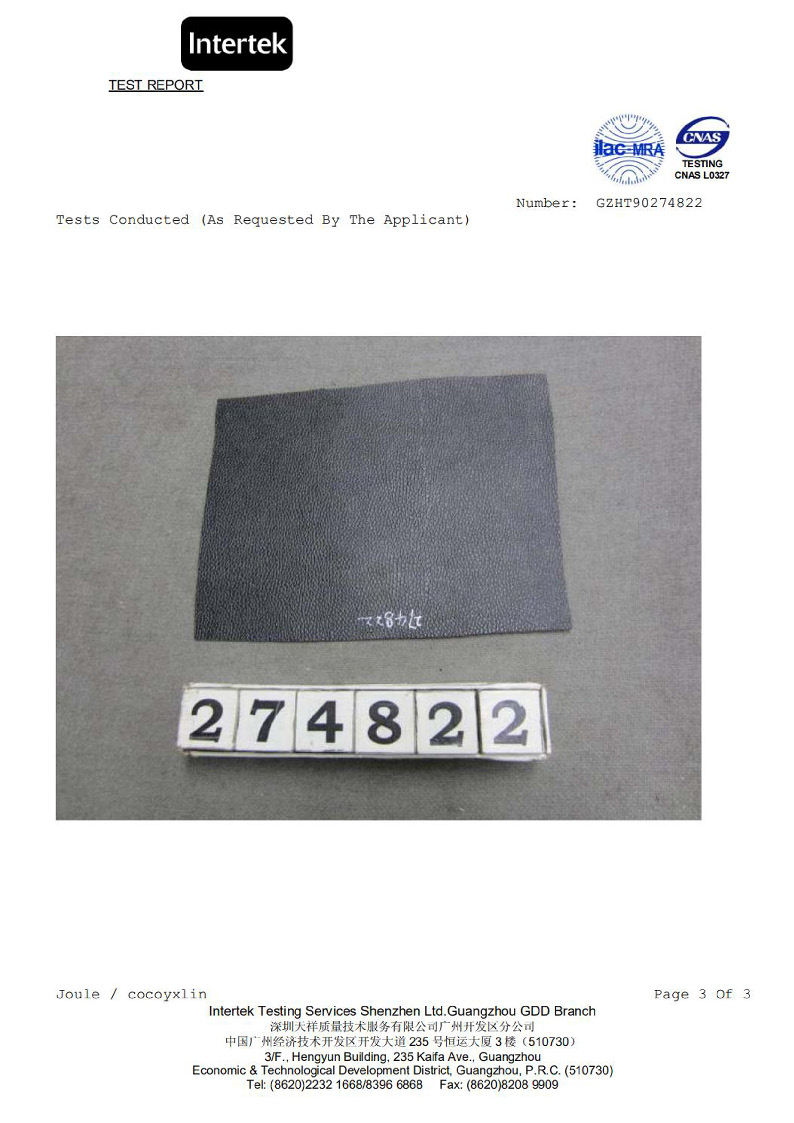

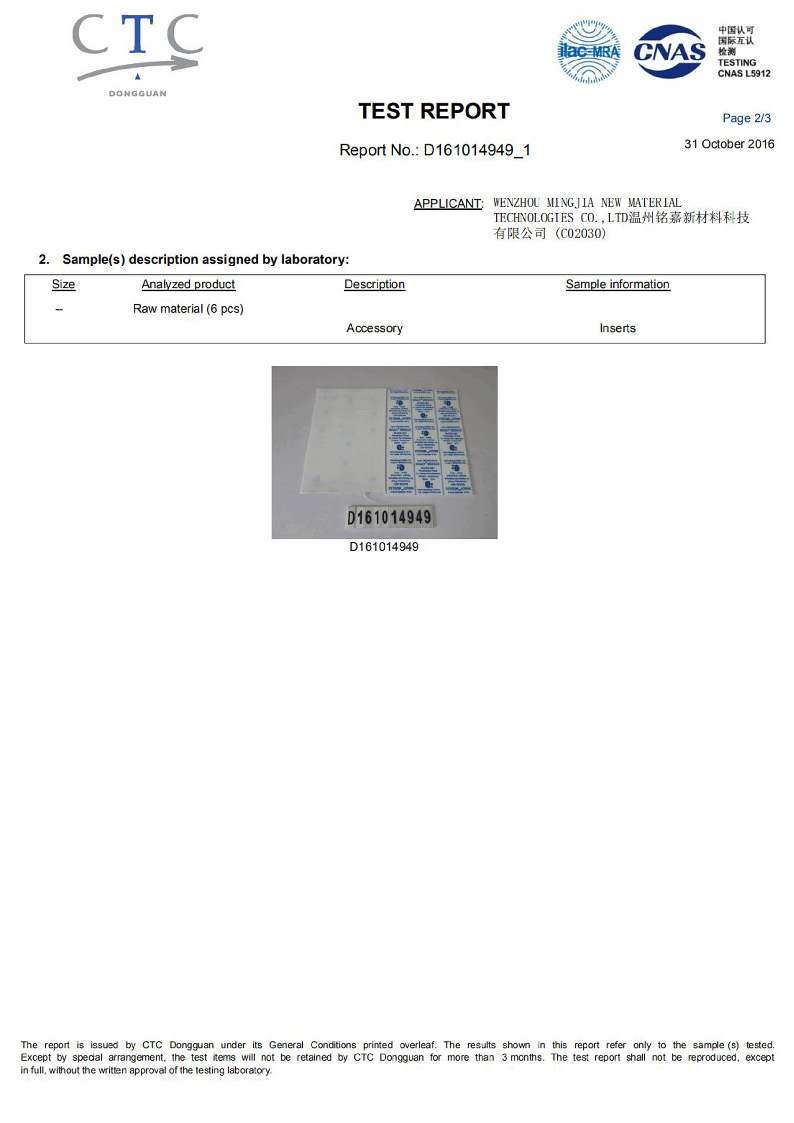

Raw Material Certifications